Before I talk about the 3D printer, I have to admit I have a bit of a grudge against Formlabs. You see, back when I was writing my final anticipation in university on the accessibility of 3D printing, I asserted that while FDM 3D printing has become low cost and easy to use, other technologies such as SLA have not. Resin systems like SLA remained at multi hundred thousand dollar price points and were messy and not user-friendly. At that time, this statement held true. However, one week later in September of 2012, Formlabs dropped the Form 1 on Kickstarter – a true SLA 3D printer for under three thousand US dollars, ready to run right out of the . This, of course, made my entire justification null and void, prompting me to delete that entire paragraph. Although, honestly, that whole document I wrote back then is probably just as dated by now. But seriously, Formlabs set a new standard for affordable SLA. So, how far have they come with the Form 2, and is it really worth three and a half thousand US dollars? Well, watch to find out. Let's quickly cover the specs. The Form 2 comes ready to run, only requiring you to fit the resin tank, build platform, and resin cartridge of your choice. It has a build volume of 145 by 145 by 175 millimeters, which may sound small, but considering that SLA 3D printers tend to have smaller build volumes due to their higher detail capabilities, this is actually a larger SLA printer, especially at this price point. It's quite similar to the Moai that I tested a little while ago, but it has a little bit more X&Y to play with. If you haven't heard of SLA 3D printers before, it stands for...

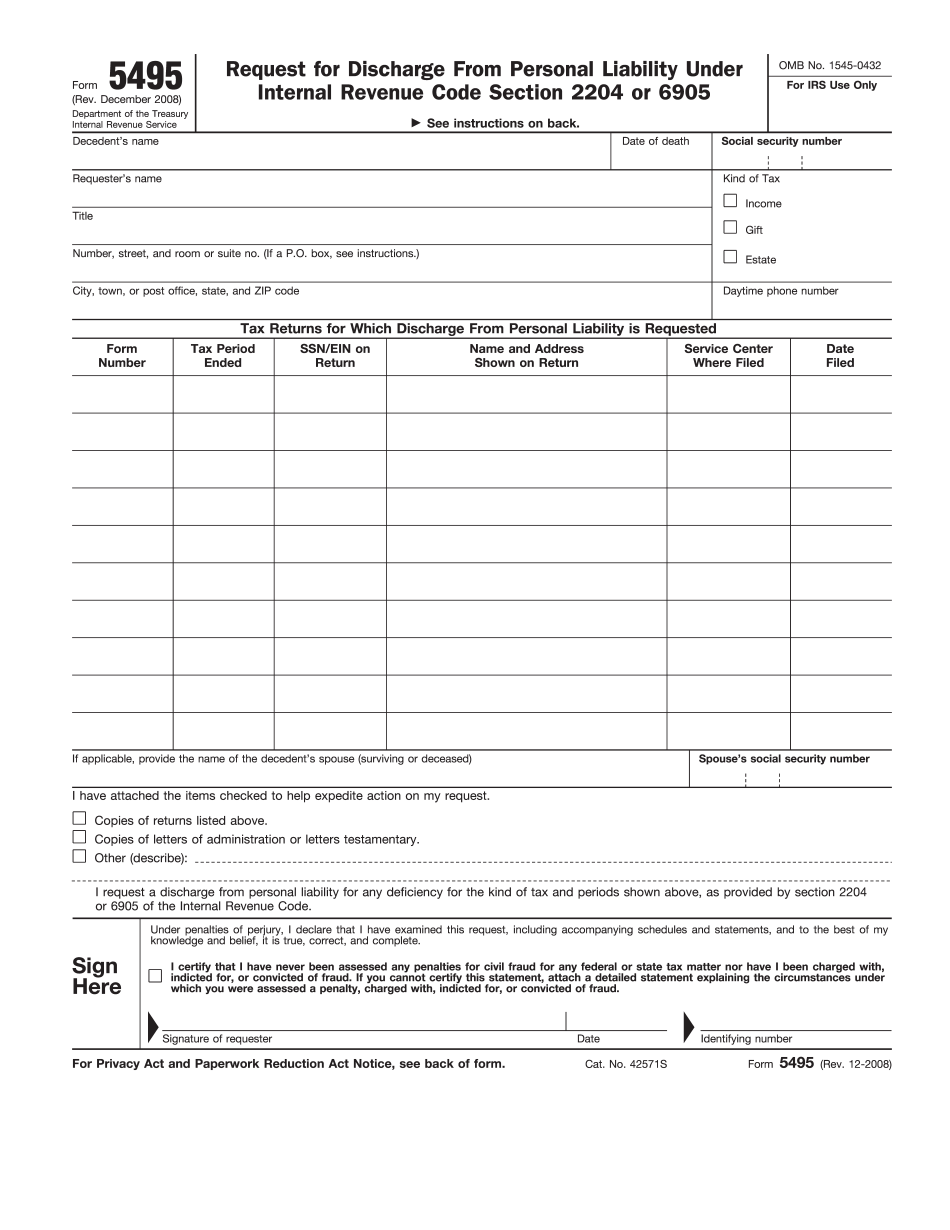

Award-winning PDF software

Video instructions and help with filling out and completing What Form 5495 Testimonials